Quilting for luxury leather goods: the art of enhancing leather with elegance and precision

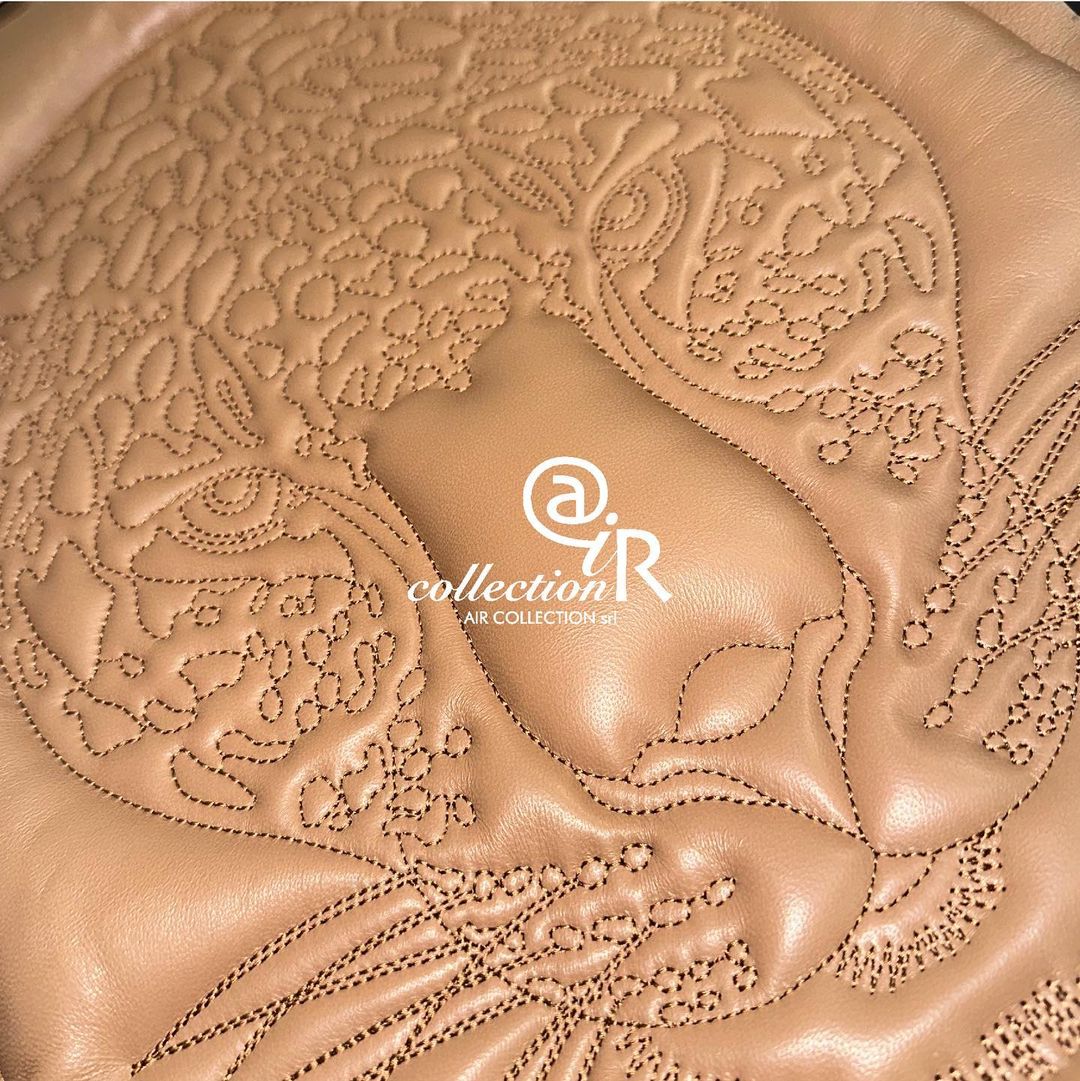

In the glittering landscape of luxury fashion and design, few details can communicate elegance, craftsmanship and intrinsic value like quilting on leather. This technique, which immediately conjures up images of iconic handbags, sumptuous car interiors, and sophisticated accessories, is more than just decoration. Quilting for luxury leather goods is a perfect marriage of textile artistry and leather craftsmanship, a process that lends three-dimensionality, texture and an unmistakable tactile and visual allure to the finest materials.

At Air Collection, we deeply understand the power of this detail. Our expertise in high-end industrial embroidery naturally extends to quilting, enabling us to offer luxury brands precise, innovative and qualitatively impeccable solutions. But what exactly is quilting applied to leather and why is it so sought after in the luxury sector?

What is quilting on leather? Defining a timeless classic

Quilting, in the context of leather goods, involves sewing together multiple layers of material-typically the outer leather, an inner padding (such as wadding, thin foam or other technical materials) and sometimes a lining-following a predefined geometric or decorative pattern. The seams create “cells” or reliefs that bring the pattern to life, adding volume, softness and strength to the overall structure of the object.

Unlike simple decorative embroidery, quilting has both an aesthetic and structural function. It does not merely add a pattern, but changes the very nature of the leather surface, making it more full-bodied, pleasing to the touch, and visually dynamic.

Why is quilting a must-have in luxury leather goods?

The widespread adoption of quilting in the luxury segment is no accident. Several factors contribute to its iconic status:

- Refined and recognizable aesthetics: motifs such as diamond matelassé, squares, parallel lines or chevrons have become synonymous with luxury. They offer an immediate visual language that communicates quality and attention to detail. Many brands have made specific quilted patterns a distinctive element of their identity.

- Added tactile value: quilted leather invites touch. The softness of the padding combined with the texture of the stitching creates a unique sensory experience that amplifies the perception of luxury.

- Structural enhancement: especially with softer or thinner leathers, quilting lends body and support, helping bags and accessories maintain shape over time and better withstand wear and tear.

- Perception of craftsmanship: even when made with advanced machinery, quilting evokes a sense of meticulous and complex work. It signals an investment in sophisticated techniques, distinguishing the product from simpler, more industrial alternatives.

- Creative versatility: although classic patterns exist, modern technology allows endless variations. Custom designs can be created, logos can be incorporated, and different densities and thicknesses can be played with, giving designers broad expressive freedom.

The process: where technology and craftsmanship meet

Making flawless quilting on fine leather requires a carefully controlled process, which at Air Collection we manage with the utmost precision thanks to our industrial embroidery technologies:

- Design and planning: it all starts with pattern definition. Using advanced CAD software, the design is digitized with pinpoint accuracy, defining stitch paths, stitch density and pattern size. This stage is crucial to ensure perfect replicability and adaptation of the pattern to the specific shapes of the final product (e.g., panels of a bag, car seats).

- Materials preparation: the leather is selected and cut according to specifications. It is then paired with the chosen padding layer (the nature of which will influence the final result in terms of volume and softness) and, if necessary, with a lining or support fabric. The choice of materials is crucial: each type of leather reacts differently to needle piercing and thread tension.

- Machine setup: this is where our expertise comes in. Industrial embroidery machines are set up specifically for quilting on leather. This includes choosing the needle (specific for leather, to avoid rips or excessive holes), fine-tuning the thread tension (top and bottom) to avoid curling or marks on the leather, and selecting the most suitable thread (often high tenacity polyester or nylon, to ensure durability and strength).

- Quilting execution: the “sandwich” of materials is placed on the machine, which executes the programmed design with absolute speed and precision. Our multi-head machines make it possible to work on several pieces simultaneously, ensuring production efficiency without compromising quality. The stability and power of industrial machines are essential to handle the thickness and strength of leather and upholstery.

- Quality control: each quilted piece is meticulously inspected for stitch regularity, absence of defects, correct thread tension and fidelity to the original design. This step ensures that only pieces that meet the very high standards of luxury proceed to the next stages of assembly.

Pattern types and customization: beyond the classic rhombus

Although diamond matelassé is perhaps the most iconic, the possibilities offered by quilting are vast:

- Geometric patterns: squares, vertical/horizontal/oblique lines, chevrons, hexagons, concentric circles.

- Organic or figurative patterns: stylized floral designs, waves, abstract patterns.

- Logo quilting: incorporation of the brand logo within the quilted pattern.

- Combination effects: alternating quilted and smooth areas, or combination of different patterns on the same product.

The real strength lies in customization. Thanks to the precision of our technologies, we are able to translate the most specific visions of designers into reality, creating unique and exclusive patterns that become the stylistic signature of a collection or brand.

The challenges of quilting on leather and how we overcome them

Working with leather presents unique challenges:

- Delicacy of the material: leather can mark, scratch or deform if not handled properly or if the thread tension is excessive.

- Irreversibility of stitching: unlike fabric, every needle hole in the leather is permanent. There is no room for error.

- Thickness management: quilting multiple layers, including padding, requires powerful machines and specific needles.

- Consistency: ensuring that the pattern is identical on all pieces and across the entire surface, even on curves and corners, requires absolute precision.

At Air Collection, we meet these challenges through:

- Advanced technology: embroidery/quilting machines designed for heavy and delicate materials, with digital tension control and precise positioning systems.

- Experience and expertise: highly skilled technicians who know the specifics of different types of leather and how to optimize machine parameters.

- Rigorous selection of consumables: use of the highest quality needles and yarns specific to leather goods.

- Proven processes: standardized operating procedures and stringent quality control at every stage.

The future of luxury quilting

Quilting will continue to be a mainstay of luxury leather goods, evolving with trends and technologies. We see a growing interest in:

- Micro-quilting: smaller, more detailed patterns.

- Innovative combinations: quilting combined with digital printing, embossing or other decorative techniques.

- Sustainable materials: application of quilting to vegetable-tanned leather, recycled leather or innovative alternatives to leather, always with an eye to sustainability.

- Extreme customization: development of increasingly unique patterns related to the identity of the individual brand or customer.

Your partner for excellence in quilting

Quilting for luxury leather goods is much more than a technique: it is a style statement, a symbol of quality craftsmanship, and a way to add tangible and intangible value to exclusive products. It requires a delicate balance between aesthetic sensitivity, knowledge of materials and technological mastery.

At Air Collection, we provide luxury brands with our deep experience in industrial embroidery and state-of-the-art manufacturing capabilities to create quilting on leather that meets the highest standards of precision, beauty and durability. We are the ideal partner to turn your creative ideas into tangible realities, ensuring flawless results that enhance the prestige of your collections.