The art of weaving: a journey through techniques and materials in embroidery

Pattern design in weaving: the heart of textile creativity

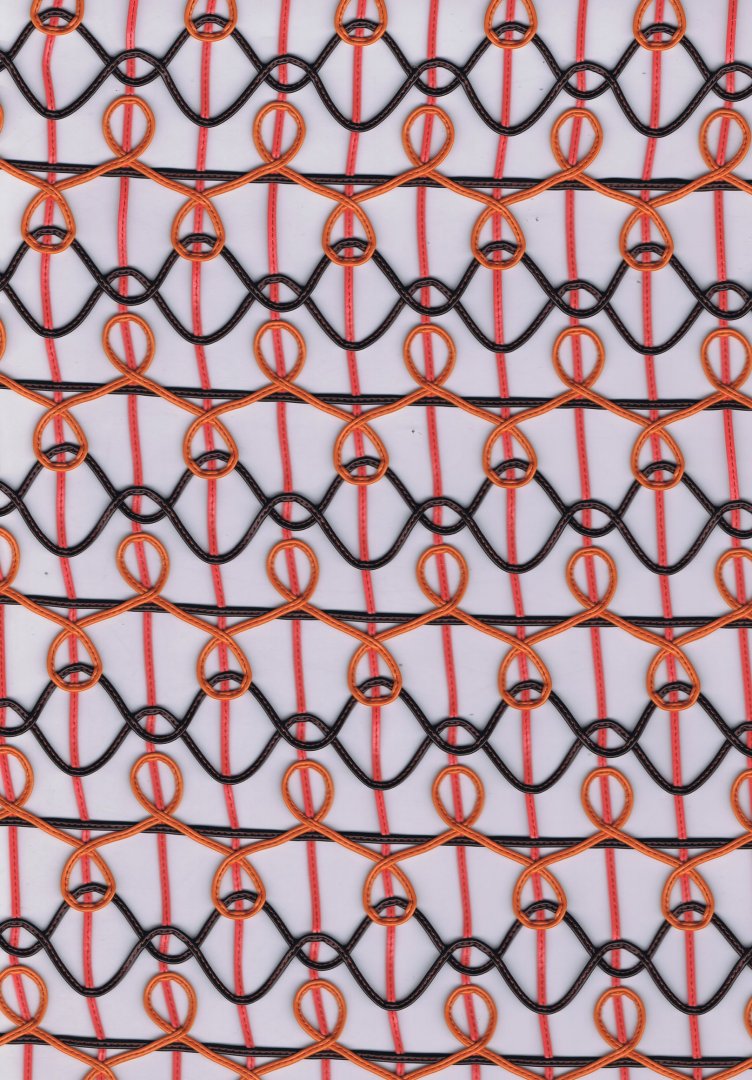

The design of weaving patterns is a key step that requires both creativity and technical precision. Designers work closely with artisans to develop detailed designs that not only reflect the latest fashion trends but are also technically feasible. Using advanced design software, makers can experiment with a wide range of shapes and patterns, ensuring that every detail is perfectly aligned with the desired aesthetic vision. This approach not only improves production efficiency, but also ensures that the end result is visually impressive and of high quality.

Material selection for unique weaves: from cotton to metal wires

Material selection is critical to successful weaving. Materials as diverse as cotton, silk, leather, and metallic threads offer a wide range of textures and visual effects, making each piece unique. The choice of material depends on the design, the end use of the fabric, and the desired characteristics of the finished product. Natural materials such as silk and cotton are preferred for their softness and durability, while metallic threads are chosen to add an element of shine and drama. The ability to combine these materials in innovative ways not only elevates design quality but also helps set new trends in fashion and textile design.

Fabric preparation: the basis for high-quality weaves

Fabric preparation is an essential step in the weaving process. Before the threads can be processed, the base fabric must be properly prepared to ensure that the weave is not only aesthetically pleasing but also durable. This includes choosing high-quality fabrics and treating them with techniques that improve their stability and manipulability. Often, fabrics are plaited or treated with sizing that facilitates their processing. A well-prepared fabric not only makes the craftsmen's work easier, but also ensures that the woven details fit together harmoniously without causing deformation or damage over time.

Manual and mechanical braiding techniques: a comparison of methods

Braiding techniques can vary significantly depending on whether you opt for manual or mechanical methods.

Manual weaving allows for unparalleled customization and detailed design control, ideal for custom or high-fashion pieces where every detail counts.

On the other hand, mechanical techniques, made with specialized embroidery machines, offer greater efficiency and uniformity, making them suitable for mass production of pieces that require consistency and repeatability.

Each method has its own specific advantages, and the choice between manual and mechanical will depend on the design goal, the scalability of the project, and the needs of the market.

Fixing and finishing weaves: ensuring longevity and aesthetics

Fixing and finishing weaves are crucial steps that affect both the aesthetics and durability of the finished product. After weaving, it is critical that the threads are securely fastened to the fabric to prevent them from fraying or coming apart with use. Methods such as hidden seams or the use of fabric-specific adhesives are commonly employed to ensure that each element stays in place. In addition, finishing processes, such as ironing or surface treatments, are essential to give the fabric a defined and professional appearance.

These steps not only improve the visual appearance of the woven fabric but also increase its resistance to wear and tear and warping, ensuring that it retains its beauty over time.

Quality control in weaves: high standards for flawless results

Quality control is a crucial step in the processing of weaves, ensuring that each finished product meets the high standards required both in terms of aesthetics and functionality. This process begins as early as the initial materials inspection and continues through each stage of production.

Quality control specialists meticulously examine each piece to ensure that the weave is perfectly executed, that there are no defects in the threads, and that the design matches exactly what is specified in the technical drawings.

Precision measuring tools and visual inspection techniques are commonly used to detect any irregularities that could compromise the final quality of the product.

Maintaining high quality standards not only enhances the embroidery mill's reputation but also ensures that customers receive long-lasting and visually stunning products.

From embroidery mill to customer: packaging and delivery of the weaves

Once quality control is completed, the packaging and delivery stage of weaves becomes critical to preserve the integrity of the product during transport.

Properly designed packaging is essential to protect delicate items from physical damage, exposure to moisture, and dust contamination. Packaging materials, such as bubble wrap, styrofoam, and rigid cardboard boxes, are selected based on the nature of the product and the transport distance. Each piece is carefully packed, ensuring that it remains motionless within the package to prevent any movement that could cause abrasion or misalignment of the weave. These details in packaging not only ensure safety during transport but also reinforce the perception of quality and care that the end customer associates with the brand.