The art of sequins: from design to finishing

Fashion design with sequins: combining art and technology

Sequined fashion design is a process that combines the art of design with the precision of technology. Designers use advanced design software to create and visualize patterns that incorporate sequins, allowing them to experiment with different arrangements and effects before actual production. This creative process is critical to producing designs that are not only visually appealing, but also technically feasible. The ability to preview the end result digitally helps them make informed choices about sequin arrangements, optimizing material use and reducing waste during the production phase.

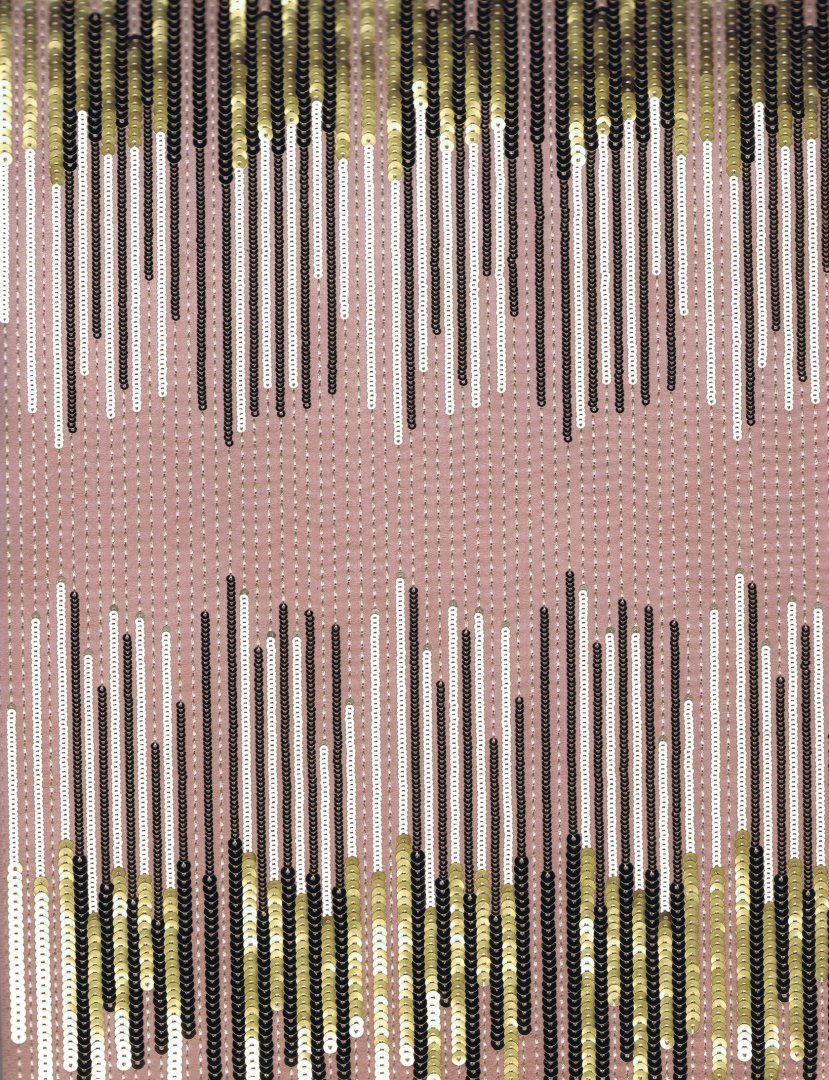

How to choose the perfect sequins: materials, colors and sizes

Selecting sequins is an art that requires a deep understanding of materials and a keen eye for color and size. Sequins can be made of a variety of materials, such as plastic, metal, or fabric, each with specific light reflection properties and weight. The choice of material will affect not only the appearance of the finished garment but also its comfort and usability. In addition, the size of sequins varies from small to large, allowing designers to create different levels of detail and texture. The available color palette is almost limitless, offering the freedom to experiment with color gradients and bold contrasts, which are crucial to creating unique designs that pique the consumer's visual and emotional interest.

Fabric preparation for sequin applications: essential techniques

Fabric preparation is a critical step in the sequin application process. Before proceeding, it is essential that the fabric be stretched and stabilized, often using a frame to keep it smooth and wrinkle-free. This step is critical to prevent the fabric from warping or shifting during application, thus ensuring a clean and precise end result. Depending on the type of fabric and design desired, specific treatments can also be applied to improve sequin adhesion. The use of specific primers or adhesives can facilitate application and improve the durability of the decoration, especially in more stretchy or textured fabrics.

Sequin hand application techniques: craft skills at work

The manual application of sequins requires considerable craftsmanship and attention to detail. Using a needle and thread, artisans stitch each sequin individually, carefully following the predetermined design. This technique allows maximum flexibility in terms of design and can be adapted to create complex and detailed visual effects.

Alternatively, the use of textile glue or special adhesives offers a faster but equally effective method that is particularly useful for large-scale applications or on fabrics that do not readily lend themselves to stitching. These methods not only ensure that the sequins adhere but also ensure that the decoration remains intact even with frequent use or washing.

Revolutionizing fashion with sequin embroidery machines

Sequin embroidery machines represent an advanced technology that has revolutionized the way sequins are applied in fabrics. These machines, programmed to follow complex designs, can apply sequins with incredible precision and speed, significantly reducing production time and increasing the consistency of results.

The ability of these machines to work with different types and sizes of sequins makes them extremely versatile, making them ideal for mass production of garments or accessories. By using automated application techniques, manufacturers can not only maintain a high standard of quality but also experiment with designs that would be too complex or expensive to make manually.

Fixing and finishing sequins: ensuring durability and quality

Fixing and finishing sequins are critical steps to ensure that the decorations not only remain attractive but also functional over time. After the sequins have been applied, either manually or by machinery, it is crucial to ensure that they are securely attached to the fabric. This often involves an additional step of stitching to reinforce sequins that may be only partially attached with adhesive or preliminary stitching.

Finishing then includes checking the alignment of the sequins and correcting any defects to ensure a clean, even result. These details not only increase the strength of the decorated fabric but also enhance its aesthetic appearance, essential for products that promise quality and durability.

Quality control in sequin application: high standards for luxury products

Quality control in sequin application is a pillar that upholds the reputation of luxury fashion manufacturers. Every garment or accessory decorated with sequins must be scrupulously examined to ensure that the application has been done correctly. Quality inspectors look for defects such as missing, misaligned, or inadequately attached sequins that could compromise both the aesthetics and functionality of the product.

Maintaining high standards during this stage ensures that each piece not only reflects the image of luxury but is also durable. Frequent quality checks help prevent customer complaints and reinforce brand trust, crucial elements for success in the competitive fashion market.

Packaging and delivery of sequined fabrics: protecting luxury

Packaging and delivery of sequin fabrics require special care to preserve the integrity and presentation of the finished products. To prevent damage during transport, garments are wrapped in protective materials that prevent abrasion and detachment of sequins. The use of high-quality packaging materials, such as bubble wrap and rigid boxes, is essential to ensure that products arrive to customers in impeccable condition. This attention to detail not only protects the physical product but also enhances the experience for the customer, which is critical for brands that wish to stand out in the luxury sector.