Introduction to laser processing techniques in the fashion industry

The introduction of laser cutting, ruster technology, and laser engraving has revolutionized the way designers think about and make their creations. Through the use of these tools, materials can be processed in ways that were previously unattainable, allowing for pinpoint accuracy and reduced material waste. These techniques not only meet the needs of an increasingly demanding market in terms of quality and unique design, but also push toward more sustainable and efficient production.

The ruster: laser scraping for artistic details on leather and fabric

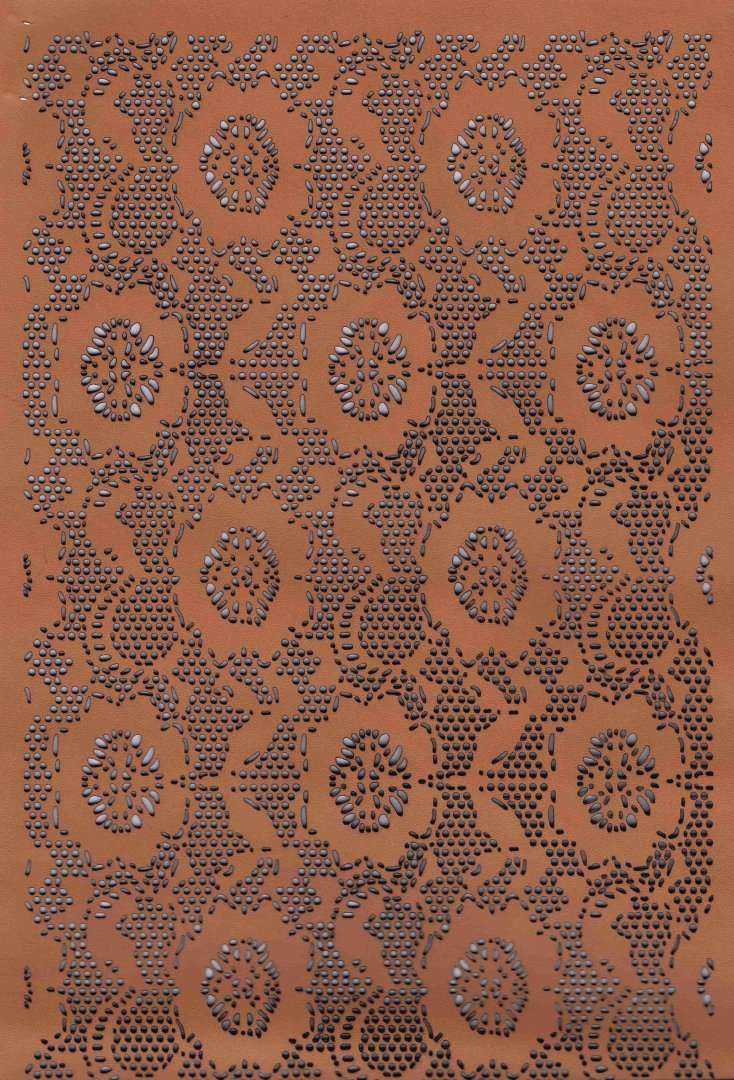

The ruster is a laser processing technique that involves "scraping" surfaces of leather or fabric to create detailed visual effects. Using a laser, surface layers of the material can be removed to draw complex images or tactile textures. This technique is particularly popular for its ability to add an artistic touch to products without compromising the structure of the underlying material.

Ruster is widely used in the creation of unique visual effects on handbags, belts, and other leather accessories, where precision and fine detailing can transform a simple object into a work of art. The ability to integrate visual and tactile textures makes each piece treated with this technique a distinct and highly personalized specimen.

Laser engraving: fountain pen precision in design details

Laser engraving is distinguished by its ability to recreate extremely precise patterns that look like they were drawn by hand with a pencil. This technique is often chosen for its excellent precision, which allows for detailed decorations on a wide range of materials, including delicate fabrics and thick leathers.

In the fashion industry, laser engraving is ideal for adding decorative patterns on leather goods accessories, such as luxury handbags or shoes, where every detail can make a difference in terms of aesthetics and perceived value. The ability of this technology to create subtle and detailed engravings without damaging the material is especially valuable to designers seeking to blend art and functionality in their products.

Laser cutting: efficiency and precision in the textile and fashion industry

Laser cutting represents one of the most revolutionary technologies in the textile and fashion industry due to its extreme precision and efficiency. This method uses a high-energy laser beam that can cut with millimeter precision, enabling it to work with a wide range of materials, including delicate fabrics and tough leathers.

The use of lasers in cutting materials not only ensures sharp, clean edges, but also significantly reduces material waste. Through the use of advanced software, patterns can be arranged to optimize the use of fabric or leather, reducing waste and contributing to more sustainable production. In addition, the ability to make quick, consecutive cuts without the need to change mechanical tools greatly improves production speed, making the process much faster than traditional cutting methods.

The future of laser machining in fashion: trends and innovations

The future of laser machining in fashion promises to be full of exciting innovations and developments. As technology advances, the possibilities for laser use expand, offering designers new avenues to explore creativity and customization.

Emerging trends indicate an increase in the use of lasers to create not only cuts and engravings, but also to develop new textures and material effects that were previously impossible. In addition, the integration of lasers with other digital technologies, such as 3D printing and artificial intelligence, could further redefine the boundaries of fashion production, leading to even greater customization and automated production processes that respond in real time to market needs.